According to experts, the global auto industry is projected to lose $110 billion in revenue during 2021 due to recent semiconductor chip shortage.

There are number of reasons which worsened the chip shortage situation. First of all the Covid-19 pandemic is one of the main element, apart from that a fire in the chip making plant near Tokyo, and severe weather conditions in the Texas also disturbed the production.

During the early days of the pandemic companies shut down production facilities, hampering their ability to keep up with surging demand for products needed while sheltering at home.

Experts forecasted that the manufacture of 3.9 million vehicles will be disturbed in this year due to chip shortage.

Read more: Samsung partners with Hyundai Motors to develop car chips

In the wake of this critical scenario, the Biden administration ordered a 100-day review regarding country’s supply chain. In US $2 trillion infrastructure, almost $50 billion is allocated for the American semiconductor industry.

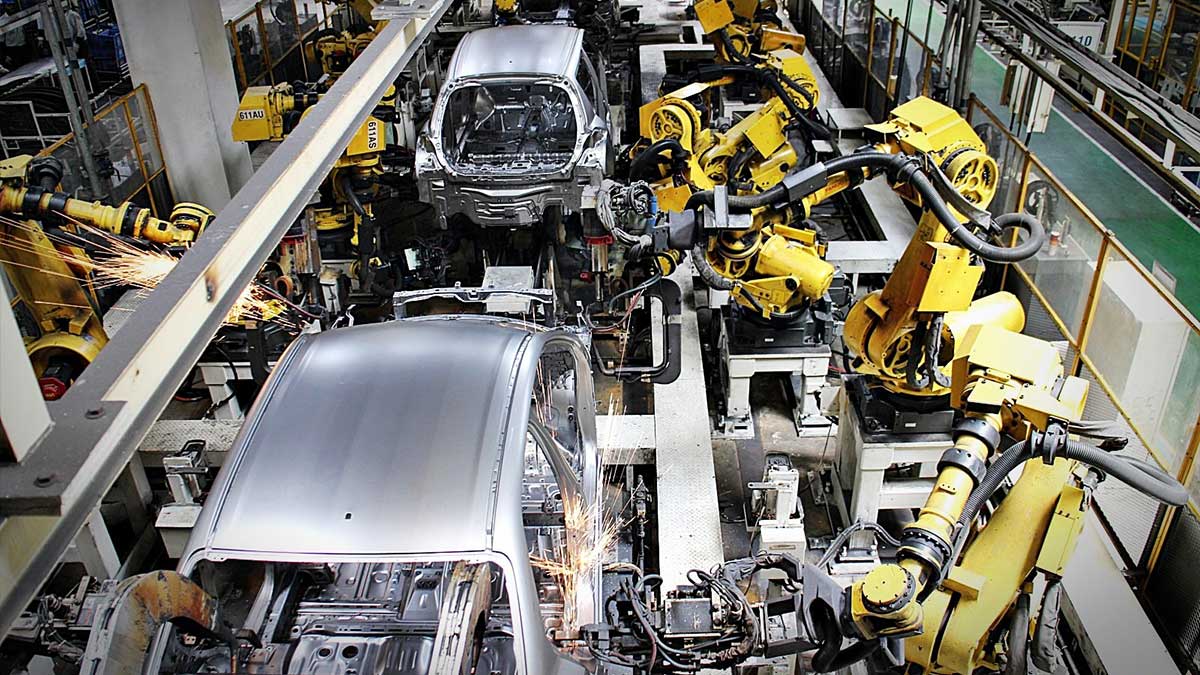

GM and Ford cutting production at several plants due to chip shortage

Due to the semiconductor scarcity, automakers such as Ford and General Motors forecast huge profits losses this year. Ford estimates that the scenario will cost the company $2.5 billion in 2021. The semiconductor shortage is expected to cost GM $1.5 billion to $2 billion in earnings.

Semiconductor chips are crucial part in new automobiles, especially for areas such as infotainment systems and more basic equipment like power steering and brakes.

Experts estimate that a vehicle might have hundreds, if not thousands, of semiconductors, depending on the car and its options. More complex safety and infotainment systems, as well as different types of processors, are found in higher-priced vehicles.

However, experts believed that current scenario likely to change in the second quarter of the year and then the operation will run smoothly during the year 2022.